- Your cart is empty

- Continue Shopping

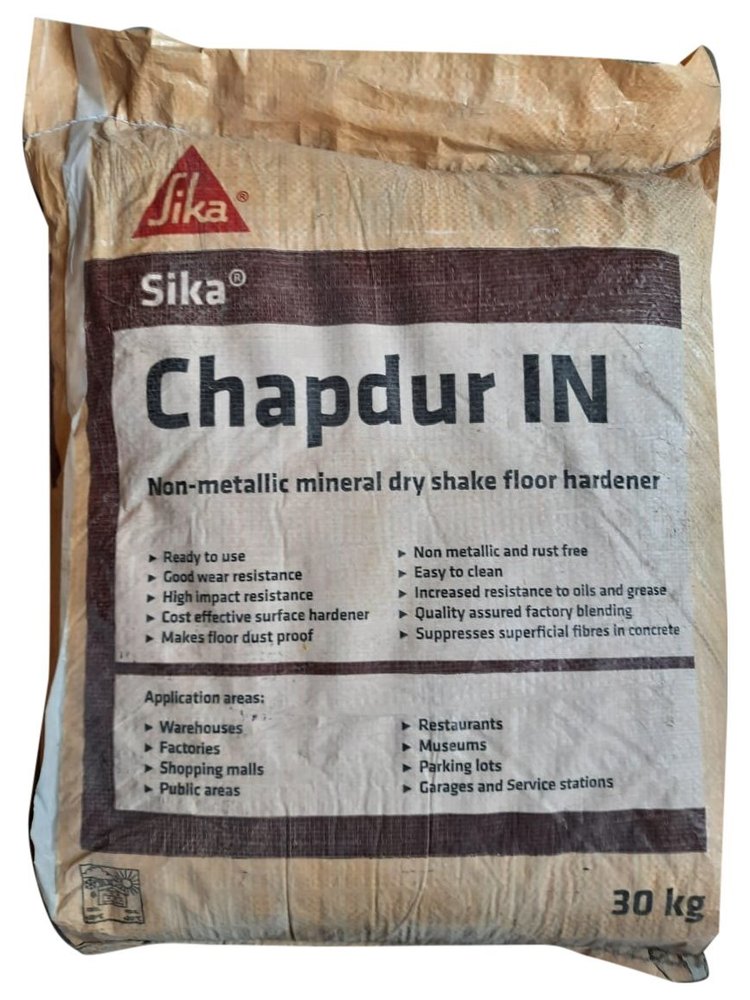

SIKA CHAPDUR (30 Kg Bag)

Check Availability

Original price was: ₹550.00.₹485.00Current price is: ₹485.00.

Bulk Order →

Non-metallic mineral dry shake floor hardener

Sika Chapdur IN is a one part, preblended, coloured mineral dry shake hardener for concrete comprising of cement, specially selected natural mineral aggregates, admixtures and pigments. Sika® Chapdur IN provides a extremely hard wearing and abrasion resistant topping for monolithic floors. When sprinkled and trowelled into fresh wet concrete floors, it forms a coloured, dense and wear resistant smooth surface.

- Ready to use

- Good wear resistance

- High impact resistance

Product Description

USES:-

Sika Chapdur (IN) may only be used by experienced professionals.

Suitable for use in all cases where floors are subjected to severe mechanical wear and there is a need to apply special hard wearing surface coverings, such as:

- Warehouses

- Factories

- Shopping malls

- Public areas

- Restaurants

- Museums

- Parking lots

- Garages and Service stations

PRODUCT INFORMATION:-

Chemical Base;-

Natural mineral aggregates graded and mixed with cement, admixtures and pigments

Packaging:-

30 kg bags

Appearance / Colour:-

Natural concrete grey powder

Shelf Life;-

12 months from date of production

Bulk Density:-

1.5 ± 0.1 kg/L at +27 °C

APPLICATION INFORMATION:-

Consumption:-

| Application | Product | Consumption |

| Light duty |

Sika® Chapdur IN |

3.5–4.0 kg/m2 |

| Medium duty |

Sika® Chapdur IN |

4.5–5.0 kg/m2 |

| Heavy duty |

Sika® Chapdur IN |

5.5–6.0 kg/m2 |

Layer Thickness:-

2.5–3.0 mm at dosage of ~5.0 kg/m2

Ambient Air Temperature;-

+5 °C min. / +35 °C max.

Relative Air Humidity:-

30% min. / 98% max.

Substrate Temperature:-

+5 °C min. / +35 °C max.

Applied Product Ready for Use:-

Foot Traffic Fully serviceable

~72 hours ~7 days

The above values are at substrate temperature of +27 °C and dependant upon the concrete reaching its design strength for serviceability and will be affected by changing ambient conditions, particularly temperature and relative humidity.

APPLICATION INSTRUCTIONS:-

SUBSTRATE QUALITY:-

- The concrete deliveries must be of consistent quality.

- A concrete slump in the range 75 to 110 mm will normally give best results.

- The slab must be of good quality concrete with a minimum water/cement ratio consistent with the production of a fully compacted slab.

- The compressive strength must be a minimum of 20 N/mm2.

- Use of Sikament or Sika Viscocrete® super plasticisers is advised to ensure the optimum quality of concrete and where fibers are used, their optimum dispersion within the mix.

- Air Entrained Concrete is not a suitable substrate for the application of dry shake hardeners.

APPLICATION:-

Application time for dryshake products is influenced by every variable which affects the placing of concrete, and can therefore vary substantially, depending on the prevailing conditions.

Dependent on the conditions, remove the surface bleed water or allow it to evaporate. Sprinkle Sika Chapdur (IN) onto the screed concrete evenly in 2 stages, first stage 60% and second stage 40%. Care must be taken to apply the product without creating ripples etc. in the concrete surface. The first application must be worked into the slab immediately followed by application of the second stage quantity of SikaChapdur (IN). Final finishing, closing pores and removing undulations can be achieved either by hand or powered trowel.

Please also note:

- Never add water to the surface where the dry shake has been applied. ▪

- Sika Chapdur (IN) results in the slab surface becoming stiff more quickly than usual. Careful trimming must take place along the edges where adjoining slabs are to be poured.

Periodical checking of the condition and development of the concrete will determine the correct time frame for each stage and sequence of application.

For mechanical application with automatic spreader and laser screed, the spreading can start almost immediately after the concrete has been levelled to allow for the hydration of the dryshake. Compaction with the trowel can start as soon as the weight of the power trowels is supported by the concrete.

For manual application, the dryshake must be spread once the concrete can be stepped on, without leaving a print deeper than 3–5 mm.

CURING TREATMENT:-

Cure Sika Chapdur (IN) immediately after finishing using clean water. For chemical curing, please consult Sika Technical Service team.

CLEANING:-

To maintain the appearance of the floor after application, Sika Chapdur (IN) must have all spillages removed immediately and must be regularly cleaned using rotary brush, mechanical scrubbers, scrubber dryer, high pressure washer, wash and vacuum techniques, etc., using suitable detergents and waxes.

Reviews

There are no reviews yet.